top of page

CHARGER/SPEAKER SYSTEM

Finished a product design / electrical project. Started off fixing and programing a 3D printer to construct a plastic housing for electrical components

SYSTEM'S FEATURES

12v and 5v Power Supplies

Used a 5 volt power supply for USB charging applications and small fans. Used a 12 volt power supply for speakers, light modules and large fans.

2 VOLTMETER, AMMETER DISPLAY

Wanted to observe how much amperage the modules used up while running and the quality the electrical wiring through the voltage readings.

WIRELESS PHONE CHARGER

Installed a wireless phone charger in such a way for easy phone docking.

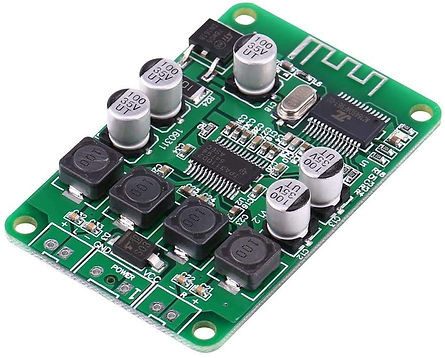

BLUETOOTH MODULE

Used a bluetooth module to be able to connect to any device to play audio to a 2 speaker system.

2 SPEAKERS

Installed 2 speakers into speaker boxes with a custom cover for protection.

MODULE TO SYNC SOUNDS TO LIGHTS

Installed a microphone light module to be able to respond to music for a light show.

3 DISCONNECTS

Installed a disconnect to cut power to the 5 volt and 12 volt power supply, and also the audio light module.

3 COOLING FANS

There are 2, 5 volt fans to cool the bluetooth module and power supply. On the outside of the main print there is an access hole for a 12 volt fan to introduce air flow to the main print.

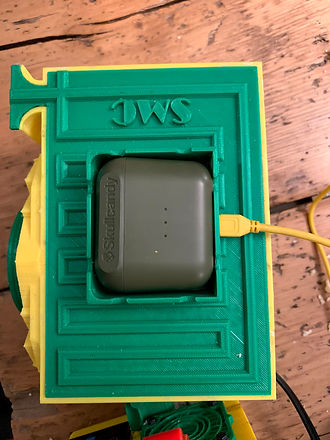

EAR BUD AND FIT BIT CHARGER MOUNTS

On the tops of the speaker boxes, there are charger stations for a fit bit watch and an earbud case.

PRINTING, CONSTRUCTION AND WIRING

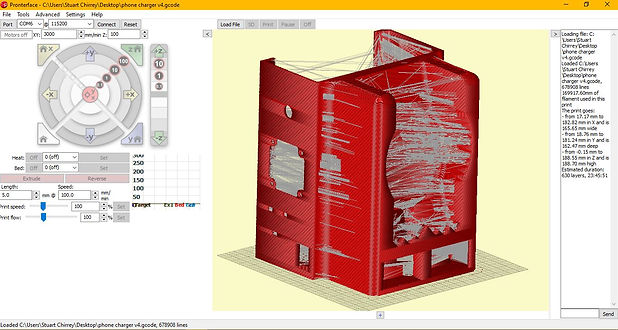

FIXING AND PROGRAMMING A 3D PRINTER

Programmed an Arduino with free Marlin firmware and adapted the code to control a broken 3D printer. With other free online software such as Slic3r and Proctorface, the printer extruded 1.5 kgs of PLA to construct the Charger/Speaker

CONSTRUCTION

Programmed an Arduino with free Marlin firmware and adapted the code to control a broken 3D printer. With other free online software such as Slic3r and Proctorface, the printer extruded 1.5 kgs of PLA to construct the Charger/Speaker

CENTER PRINT

Divided the centerpiece into 4 prints and glue them together.

Printed a backplate to exhaust the cooling fans. Also installed a press-fit top plate with a USB charger mount.

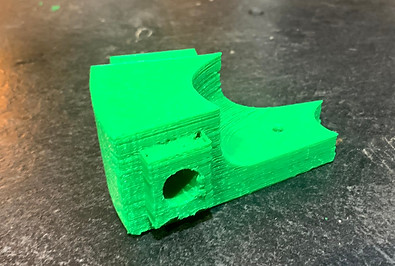

SPEAKER PRINT

Designed a speaker box for deeper sounding music experience with a connecting part for wires to travel through

WIRING JOB

Used quick-connect terminals blocks to wire in components to the main print. Soldered the power supplies and the bluetooth module into the system. Ran power and audio signals into the speaker boxes to power the lights and drive the speakers.

bottom of page